Contact : Jean-Paul ADAM (NOMADE Team)

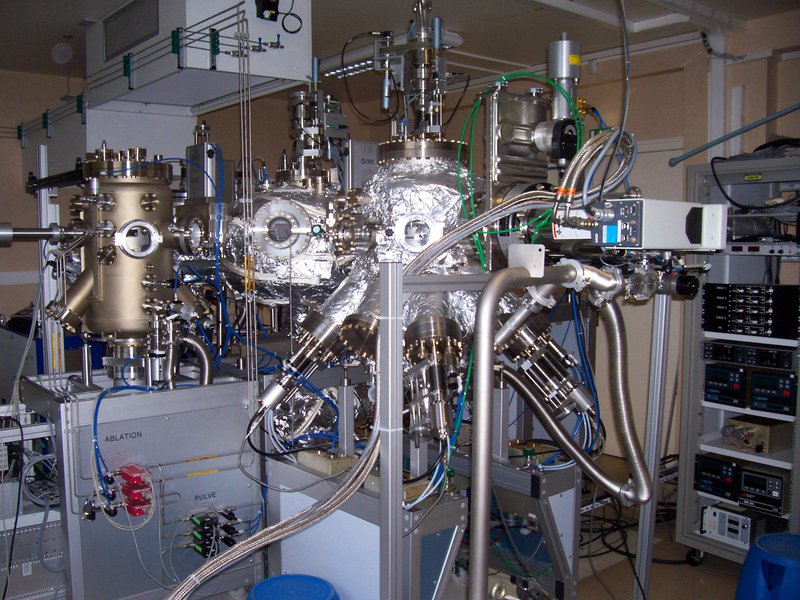

Our deposition cluster is a research tool optimized for the deposition of metals and oxides thin films at low deposition rates, under a base vacuum of 10-8 mbar and a typical argon working pressure of 5×10-4 mbar in magnetron mode. It is equipped with 8 sputtering cathodes and more than 30 available targets, and each cathode can be powered in DC or RF mode.

The sampler holder incorporates permanent magnets for in-field deposition, and it can be heated up to 400°C.

Our sputtering machine can accept 8 inch wafers, although the uniformity of the deposition is ensured only over 2 inches.

The cluster connects the sputtering system to a Chemically Assisted Ion Beam Etching tool and an UHV Pulsed Laser Deposition system, optimized for the deposition of piezoelectric materials. For exampl, a process of elaboration of a thin multi-layer CFB/MgO was developed for spintronics application.